Top 10 Tips for Choosing the Right Twisting Machine for Your Needs

Choosing the right twisting machine for your production requirements can significantly impact the efficiency and quality of your manufacturing process. In a world where precision and adaptability are crucial for success, understanding the various aspects of twisting machines becomes essential. Whether you are in the textile industry or involved in the production of specialized cables, the right machine can enhance your product's reliability while minimizing waste and operational costs.

When selecting a twisting machine, several factors must be considered, including the type of materials you will be working with, the desired output speed, and the specific twisting techniques you plan to employ. These considerations can influence not only the performance of the machine but also the final quality of your products. By carefully assessing your needs and aligning them with the capabilities of available machines, you can make an informed decision that will benefit your operations in the long term.

In this article, we present the top 10 tips for choosing the right twisting machine tailored to your needs. By following these guidelines, you will be better equipped to navigate the selection process, ensuring that your investment yields optimal results and supports the overall goals of your manufacturing endeavors.

Understanding Your Twisting Needs and Requirements

When choosing the right twisting machine, understanding your specific twisting needs and requirements is crucial for optimizing production efficiency and quality. Each twisting machine uniquely accommodates various materials, from fine threads to heavier cables, necessitating a thorough assessment of the types of materials you intend to twist. According to a report by the International Textile Machinery Association (ITMA), approximately 30% of machine malfunctions are linked to mismatched equipment and material specifications. Thus, aligning your machine choice with your operational materials can significantly reduce downtime and maintenance costs.

Additionally, production volume plays a significant role in determining the appropriate twisting machine. The market demand for twisted products continues to grow, with a projected annual growth rate of 4% in the textile industry over the next five years, as indicated by a report from Allied Market Research. Businesses must evaluate their daily and monthly production targets to select a machine that can meet their output requirements without compromising product quality. Factors such as spindle speed, twisting method, and integration capabilities with existing systems should also be taken into account to enhance overall productivity and workflow.

Key Features to Look for in Twisting Machines

When selecting the right twisting machine for your specific needs, it's essential to focus on several key features that can significantly enhance your production efficiency and quality. Firstly, consider the machine's twist capacity, which defines how many strands it can handle at once. A higher capacity allows for increased productivity, making it an ideal choice for high-volume operations. Additionally, the twist direction, whether S or Z, is important to match the requirements of your materials and final product specifications.

Another critical feature to evaluate is the machine's ease of operation and automation level. Machines with user-friendly interfaces and programmable settings can save time and reduce the likelihood of errors, which is vital for maintaining consistent output quality. Furthermore, look for machines that offer adjustable tension controls; this feature is crucial for achieving the desired twist without compromising the integrity of the fibers. Lastly, durability and maintenance requirements should not be overlooked. Investing in a robust machine with easy access for maintenance will ensure longevity and minimize downtime, ultimately benefiting your manufacturing process.

Evaluating Different Types of Twisting Machines

When evaluating different types of twisting machines, it's essential to consider the specific needs of your production environment. Twisting machines vary significantly in design and functionality, so understanding the distinctions between models can greatly impact your efficiency and output quality. For instance, some machines are designed for high-speed operations ideal for mass production, while others may focus on precision twisting for specialty fibers. Analyzing the materials you will be working with—from synthetic fibers to natural threads—can help narrow down your choices.

Moreover, assessing the automation level of various twisting machines is crucial. Fully automated machines can streamline your workflow and reduce labor costs, but they may also require a higher initial investment. On the other hand, semi-automated options can offer flexibility and are often easier to maintain, allowing for quick adjustments to different production requirements. By weighing these factors, you can determine which type aligns best with your operational goals and budget, ensuring you select the right twisting machine for your unique production needs.

Assessing Budget and Cost-Effectiveness

When it comes to selecting the right twisting machine, assessing your budget and cost-effectiveness is paramount. Understanding your financial limitations not only helps narrow down your options but also ensures you make a sound investment. Consider the total cost of ownership, including maintenance, parts replacement, and energy consumption, which can significantly affect your long-term expenses. A machine that seems affordable upfront might lead to hidden costs over time, so thorough research is essential.

One crucial tip is to evaluate your production needs against the machine's capabilities. If you require high volume and speed, investing in a more advanced model may be worth the cost. On the other hand, for smaller operations, a basic model could suffice, allowing you to save money while meeting your immediate requirements.

Another aspect to consider is the resale value of the machine. Some twisting machines retain their value better than others; understanding this can help you make a more informed decision.

Finally, don't overlook the importance of versatility and technology. Machines equipped with updated features may come at a higher price but can offer significant savings in labor and materials. This innovation often leads to enhanced efficiency and reduced waste, contributing to overall cost-effectiveness. As you assess your budget, prioritize machines that align with your production goals and offer the best return on investment.

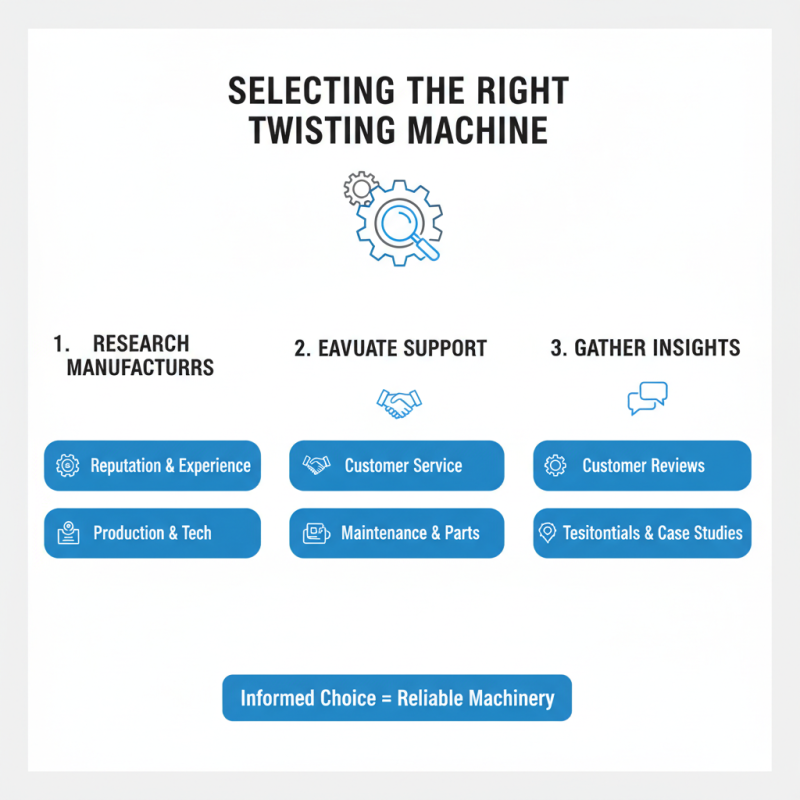

Researching Manufacturers and Customer Support Options

When selecting the right twisting machine, it is crucial to thoroughly research manufacturers and their customer support options. Understanding the reputation of a manufacturer can greatly impact the overall reliability and efficiency of the machinery you choose. Start by looking into their experience in the industry, production capabilities, and the technology they use. Reviews and testimonials from previous customers can provide valuable insight into their experience with the equipment and the company's service quality.

Additionally, evaluating customer support options is essential before making a decision. A manufacturer that offers comprehensive support, including installation, training, and ongoing maintenance, ensures that your operations run smoothly after the purchase. Consider whether the manufacturer provides online resources, such as manuals and troubleshooting guides, and if they have a responsive customer service team for direct assistance. By focusing on both the manufacturer's reputation and the level of customer support they provide, you can make a more informed choice that meets your specific needs.

Related Posts

-

What is Hand Loom Weaving and How Does It Work in Modern Craftsmanship

-

Ultimate Guide to Choosing the Best Yarn Twister for Your Knitting Projects

-

Top 10 Weaving Bobbin Winders of 2023: Boost Your Efficiency by 30%

-

2025 How to Choose the Best Weaving Loom Machine for Your Needs

-

Top 10 Best Wool Looms for Crafting Stunning Projects at Home

-

2025 Top 5 Loom Fabric Trends: Innovative Designs and Sustainable Choices