Top 10 Tips for Choosing the Right Textile Machine for Your Business

Choosing the right textile machine is a critical decision for any business in the textile industry, impacting both productivity and product quality. With a myriad of options available, selecting the ideal machine tailored to specific operational needs can be daunting. The right textile machine not only enhances efficiency but also significantly contributes to the overall success and competitiveness of a business.

In this guide, we will explore essential tips to help you navigate the complexities of choosing the right textile machine. From understanding your production requirements to considering advanced technologies, each factor plays a vital role in making an informed decision. By focusing on these key considerations, businesses can optimize their manufacturing processes and ultimately achieve their desired outcomes. Whether you're a startup or looking to upgrade your existing equipment, the importance of making an informed choice in your textile machine selection cannot be overstated.

Understanding Your Business Needs and Goals

When selecting a textile machine for your business, understanding your unique needs and goals is crucial for making an informed decision. Start by conducting a thorough analysis of your production requirements. Consider factors such as the types of materials you will be working with, the desired output levels, and the complexity of your designs. By defining these parameters, you can better align the machine's capabilities with your production ambitions, ensuring a smoother workflow and higher efficiency.

Furthermore, it is essential to evaluate your long-term business objectives. Think about the growth potential of your company and how the chosen machine can support scalability. Are you looking to diversify your product range? Will you need a machine that can adapt to changing market demands? By assessing your goals from a strategic perspective, you can choose equipment that not only meets your current needs but also positions you well for future development. This foresight will allow you to invest wisely, enabling your business to thrive in a competitive landscape.

Evaluating Different Types of Textile Machines

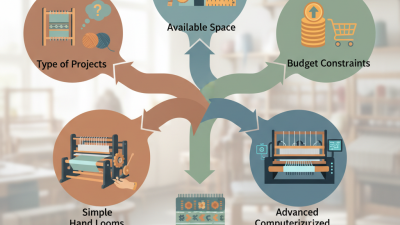

When evaluating different types of textile machines, it's crucial to consider the specific needs of your business. Textile machinery comes in various forms, each serving distinct purposes, from weaving and knitting to dyeing and finishing. Assessing the material you plan to work with is essential; for instance, if you are focusing on natural fibers, your machine requirements will differ from those necessary for synthetic materials. Understanding the scope of your production, including the types of fabrics and their respective workings, will help narrow down your options effectively.

Another important factor is the scale of production. Smaller operations may benefit from versatile machines that can handle multiple tasks, while larger manufacturers might need specialized equipment designed for high output. It's also useful to consider the technological advancements incorporated into these machines. Modern features such as automation can significantly enhance productivity and reduce labor costs, making it essential to evaluate machines that align not only with current trends but also with the long-term vision of your business. Proper evaluation ensures that you invest in machines that not only meet your immediate needs but also support future growth and innovation in your textile production line.

Analyzing the Machine's Production Capacity and Efficiency

When selecting the right textile machine for your business, assessing the machine's production capacity and efficiency is paramount. The production capacity, often measured in terms of output per hour or per shift, plays a crucial role in meeting market demands. According to a report by Mordor Intelligence, the global textile machinery market is expected to grow at a rate of 5.2% from 2021 to 2026, driven largely by advancements in machine technology that enhance production speed and reduce downtime. Machines that can optimize their output while maintaining high-quality standards can significantly improve a business's competitiveness.

Efficiency is another critical aspect when analyzing textile machines. Key performance indicators (KPIs) such as energy consumption, waste generation, and maintenance frequency provide insights into operational efficiency. A study by Research and Markets indicates that energy-efficient textile machines can reduce energy consumption by up to 30%, translating into substantial cost savings over time. Furthermore, machines equipped with automated features can minimize human error, enhance precision, and increase overall productivity. By carefully considering these factors, businesses can select equipment that not only meets their production needs but also aligns with their long-term sustainability goals.

Considering Maintenance and Support Services

When selecting a textile machine for your business, one of the critical factors to consider is the availability and quality of maintenance and support services. A reliable support network can significantly extend the lifespan of your machine and ensure it operates efficiently. Before making a purchase, evaluate the manufacturer's reputation regarding customer service. Look for companies that offer comprehensive training for your staff and have a responsive support team that can assist you with troubleshooting and repairs.

Moreover, understanding the maintenance requirements of the machine is essential. Regular maintenance not only prevents unexpected breakdowns but also helps in maintaining optimal performance levels. Check if the manufacturer provides detailed maintenance guidelines and whether they offer service contracts that include scheduled maintenance visits. This proactive approach can save your business time and money in the long run, allowing you to focus on production instead of machine-related issues. Assessing these aspects will help you choose a textile machine that not only meets your operational needs but also comes with robust support to keep your business running smoothly.

Comparing Costs and Financing Options

When selecting the right textile machine for your business, understanding the costs and financing options available is crucial. It's essential to evaluate the total cost of ownership, which includes the initial purchase price, maintenance costs, and operational expenses. Comparing different machines and their features will help you identify the most cost-effective option that meets your production needs. Additionally, consider the potential return on investment (ROI) as this will influence your overall budget and financial planning for the future.

One of the key tips is to thoroughly assess your production requirements before making a decision. This means determining the types of fabrics you will be working with and the volume of production you anticipate. Another important factor is to explore financing options; many suppliers offer financing plans that can help ease the initial financial burden. Leasing machinery can also be a viable alternative, allowing you to upgrade to newer technology without committing to a full purchase upfront. Understanding these aspects will empower you to make an informed choice that aligns with your business strategy.

Related Posts

-

2025 How to Choose the Best Weaving Loom Machine for Your Needs

-

What is Hand Loom Weaving and How Does It Work in Modern Craftsmanship

-

Top 10 Tips for Choosing the Right Twisting Machine for Your Needs

-

Top 10 Weaving Bobbin Winders of 2023: Boost Your Efficiency by 30%

-

Top 10 Best Wool Looms for Crafting Stunning Projects at Home

-

Top 7 Weave Fabric Types You Need to Know for Your Next Project