2025 How to Choose the Best Weaving Loom Machine for Your Needs

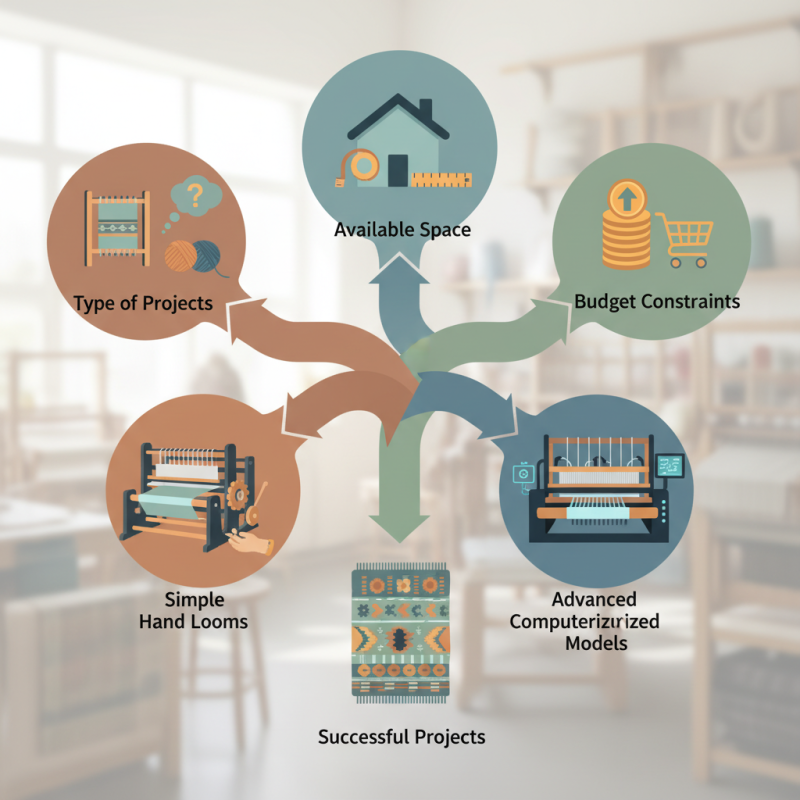

Choosing the right weaving loom machine is crucial for both novice and experienced weavers alike. With a wide array of options available in the market, understanding what features to consider can significantly enhance your weaving experience. As you embark on your journey to select the perfect loom, it's essential to weigh factors such as the type of weaving projects you intend to pursue, the available space in your workshop, and your budget constraints.

In this guide, we will explore the various types of weaving loom machines, from simple hand looms to advanced computerized models, helping you identify which one aligns best with your creative vision and practical needs. By assessing your specific requirements and preferences, you'll be better equipped to make an informed decision that will lead to both personal satisfaction and high-quality textile production. Whether you are looking to create intricate patterns or straightforward textiles, knowing how to choose the best weaving loom machine sets the foundation for successful projects ahead.

Understanding the Basics of Weaving Loom Machines

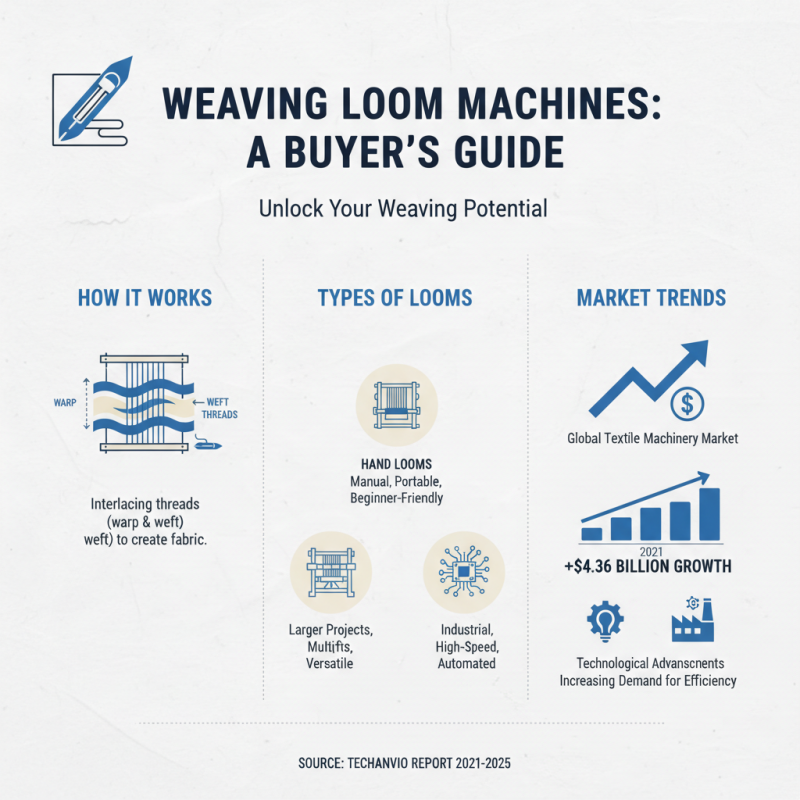

Choosing the right weaving loom machine can significantly enhance your weaving experience, but understanding the basics of how these machines operate is the first step. A weaving loom functions by interlacing threads to create a fabric, and there are several types available in the market today. According to a report by Technavio, the global textile machinery market is expected to grow by USD 4.36 billion from 2021 to 2025, driven by technological advancements and increasing demand for efficient weaving solutions.

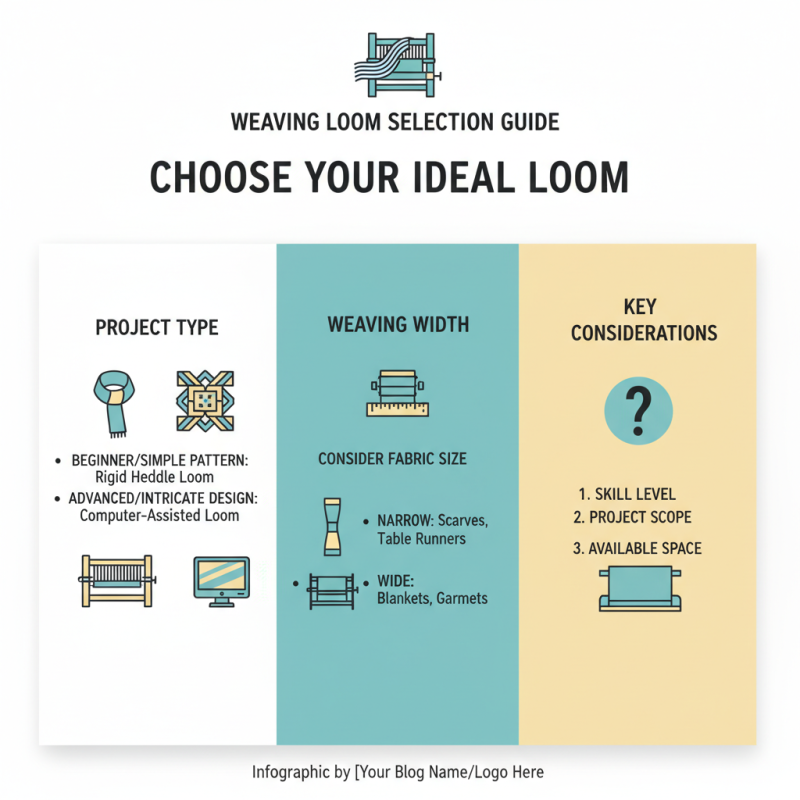

When selecting a loom, it is essential to consider the type of projects you plan to undertake. Rigid heddle looms are ideal for beginners due to their simplicity and versatility, while floor looms offer greater complexity and are suited for larger projects. Additionally, computerized looms can automate many processes, allowing for precision that can enhance intricate designs.

**Tips:** Before making a purchase, assess the space you have available, as some looms require significant room. Also, consider your budget and the types of materials you intend to weave, as different looms cater to various fibers and thread counts, influencing both the quality of the finished product and the overall weaving experience.

Key Factors to Consider When Choosing a Weaving Loom

When selecting the ideal weaving loom machine for your needs, several key factors must be taken into account. First and foremost, determine the type of projects you plan to undertake. For instance, a rigid heddle loom is perfect for beginners or those focusing on simpler patterns, while a computer-assisted loom might be more suitable for advanced weavers aiming for intricate designs. The weaving width is also crucial; consider the size of the fabric you wish to create, as looms come in various widths, affecting the versatility of your projects.

Another essential factor is the loom's construction and materials. High-quality materials not only enhance durability but also ensure a smoother weaving experience. Additionally, contemplate the loom's weight and portability, especially if you plan to transport it to workshops or classes. Finally, evaluate the price range and your budget. While it might be tempting to opt for a cheaper model, investing in a well-made loom can significantly impact your weaving experience and satisfaction in the long run. Balancing these factors will guide you in choosing the best weaving loom machine tailored to your unique needs.

Types of Weaving Loom Machines and Their Uses

When selecting a weaving loom machine, understanding the various types available and their specific uses is crucial. There are primarily three categories of weaving looms: mechanical looms, electronic looms, and hand looms. Mechanical looms, cherished for their craftsmanship, are ideal for traditional weaving projects, providing a tactile experience and full control over the weaving process. According to a report by Smith & Co. 2022, mechanical looms account for about 40% of the market, appealing to artisan weavers and hobbyists alike.

In contrast, electronic looms have surged in popularity, making up approximately 50% of the global market. These machines offer automated features that significantly enhance efficiency and precision, making them suitable for larger production runs and complex patterns. Hand looms, although representing only 10% of the market, provide an accessible entry point for beginners and those looking to engage in small-scale creations. They foster creativity and can be utilized for various textile projects, from scarves to wall hangings.

Tips: When choosing a weaving loom, consider your primary projects—mechanical looms are excellent for intricate designs, while electronic models suit larger productions. Additionally, assess the space available; hand looms require less room, making them perfect for small craft areas. Always review customer feedback and check for support services, as they can significantly influence your long-term satisfaction with the purchase.

Evaluating the Price and Quality of Weaving Looms

When evaluating the price and quality of weaving loom machines, it's important to consider several factors that impact both aspects. The first aspect to look at is the material and craftsmanship of the loom. High-quality looms are often constructed from sturdy materials like hardwood or high-grade metal, which not only enhance durability but also ensure smooth operation over time. On the other hand, looms made from inferior materials may be available at a lower price point but can lead to maintenance issues and a lack of precision in weaving.

Additionally, features such as the loom's size, type (e.g., shaft or rigid heddle), and additional capabilities should be evaluated. Machines that offer more versatility—like adjustable shedding or automatic functionality—might come with a higher upfront cost but can save time and improve the quality of the finished products in the long run.

When comparing prices, it's valuable to assess the warranty and customer support provided by the manufacturer as well. A higher initial investment in a loom that comes with extensive support can be more economical than choosing a less expensive option without assurance of quality, potentially leading to additional costs for replacements or repairs. Balancing price with features and support is key to making an informed decision.

2025 Weaving Loom Machine Price and Quality Evaluation

Maintenance and Support Options for Loom Machines

When selecting a weaving loom machine, it's crucial to consider the maintenance and support options available. A reliable loom requires regular upkeep to ensure its longevity and optimal performance. Look for machines that come with comprehensive maintenance guides, as well as warranties that cover potential repairs. It is advisable to choose brands that offer easy access to spare parts and have a reputation for durable products, reducing potential downtime due to machine failure.

In addition to maintenance, evaluate the support options provided by the manufacturer. Excellent customer service can make a significant difference, especially for novice users who may encounter challenges while operating the loom. A company that offers thorough online resources, such as tutorials and troubleshooting guides, can be invaluable. Furthermore, consider manufacturers that provide robust community support, such as forums or social media groups, where you can connect with other weavers and share insights. By prioritizing these factors, you can ensure that your weaving experience is both enjoyable and productive.

2025 How to Choose the Best Weaving Loom Machine for Your Needs - Maintenance and Support Options for Loom Machines

| Loom Type | Width Capacity | Weight | Material | Maintenance Frequency | Support Options |

|---|---|---|---|---|---|

| Hand Loom | 30 inches | 15 lbs | Wood | Annual | Online tutorials and manuals |

| Table Loom | 45 inches | 20 lbs | Metal | Biannual | Phone support and online chat |

| Floor Loom | 60 inches | 50 lbs | Wood | Quarterly | In-person workshops and online forums |

| Digital Loom | 70 inches | 70 lbs | Aluminum | Monthly | 24/7 customer support and software updates |

Related Posts

-

10 Best Yarn Winding Machines for Effortless Crafting and Production

-

Unlocking Efficiency and Precision with the Advanced Bobbin Winder Sewing Machine for Seamless Projects

-

Top 10 Best Wool Looms for Crafting Stunning Projects at Home

-

2025 Top 5 Loom Fabric Trends: Innovative Designs and Sustainable Choices

-

How to Choose the Best Bobbin Winder Machine for Your Sewing Needs

-

10 Best Yarn Types for Weaving Looms in 2023: A Comprehensive Guide