Ultimate Guide to Choosing the Right Thread Winding Machine for Your Needs

Choosing the right thread winding machine is a critical decision for businesses involved in textile, electronics, and various manufacturing industries. A thread winding machine plays a vital role in producing high-quality coils and spools, which are essential for a range of applications, from sewing threads to electrical wiring. With the ever-evolving technological landscape and the diverse needs of different sectors, understanding the various types of thread winding machines available can ensure that businesses optimize their production processes and improve efficiency.

In this ultimate guide, we will explore the key factors to consider when selecting a thread winding machine that aligns with your specific requirements. From evaluating the machine's capacity and speed to understanding the types of winding mechanisms, each aspect contributes to enhancing productivity and minimizing waste. Additionally, we will highlight common features and advanced options that can make a significant difference in the quality of the winding process. By the end of this guide, you will be equipped with the knowledge necessary to make an informed choice, ultimately leading to better operational outcomes and the success of your business.

Understanding Thread Winding Machines: Types and Functions

Thread winding machines are essential tools in the textile industry, designed to efficiently wind thread onto spools or cones for various applications. Understanding the types and functions of these machines is crucial for any business looking to optimize its production processes. Typically, there are three main types of thread winding machines: automatic, semi-automatic, and manual. Each type presents unique features suited for different production scales and operational needs.

Automatic winding machines are favored for their high efficiency and speed, equipped with advanced technology to minimize human intervention. They are ideal for large-scale operations where consistent quality and productivity are paramount. Semi-automatic machines offer a balance, allowing operators to manage the winding process while still providing some automation benefits, making them suitable for medium-sized businesses. Manual winding machines, though less common in large operations, play a vital role in smaller setups or specialized applications where flexibility and control over the winding process are required.

In addition to machine types, understanding the functions of thread winding machines is critical. These machines typically serve to ensure uniform tension and winding patterns, preventing issues such as tangling or uneven distribution of thread. Features such as tension control systems, cutting mechanisms, and programmable patterns enhance the functionality of these machines, making it easier to produce high-quality thread products tailored to specific requirements. By choosing the right type of thread winding machine and understanding its functions, businesses can significantly improve their operational efficiency and product quality.

Key Factors to Consider When Buying a Thread Winding Machine

When considering the purchase of a thread winding machine, several key factors must be taken into account to ensure that the equipment meets your specific operational needs. First and foremost, the machine's capacity is crucial; this includes the maximum spool size it can accommodate and the winding speed it can achieve. Depending on the volume of production and the types of materials being processed, selecting a machine with the appropriate capacity will directly influence efficiency and productivity.

Another important consideration is the machine's versatility. Look for features that allow you to easily switch between different thread types, sizes, and winding patterns. This adaptability can significantly enhance your production line's flexibility, enabling you to respond to varying customer demands without the need for extensive downtime or reconfiguration. Additionally, the ease of operation and maintenance should not be overlooked; a user-friendly interface and support for routine upkeep can reduce labor costs and downtime, making it a more cost-effective investment in the long run.

Comparing Automatic vs. Manual Thread Winding Machines

When considering thread winding machines, one of the most significant choices to make is between automatic and manual systems. Automatic thread winding machines boast high efficiency and precision, making them ideal for large-scale production where speed and consistency are paramount. These machines significantly reduce human labor and minimize the risk of errors, allowing businesses to maintain higher quality standards while maximizing output. Furthermore, modern automatic machines often come with advanced features such as programmable controls and automatic tension adjustments, enhancing their usability and adaptability across various thread types.

On the other hand, manual thread winding machines offer a level of control and flexibility that automated versions cannot replicate. They are often preferred by small businesses or artisans who require a hands-on approach to their craft, allowing for adjustments based on specific project needs. Manual machines can be less expensive upfront and may not require the same level of maintenance as their automatic counterparts. However, they do require more time and effort to operate, which can limit the volume of production. Ultimately, the choice between automatic and manual machines should align with the specific production demands, skill levels, and budget considerations of the user.

Ultimate Guide to Choosing the Right Thread Winding Machine for Your Needs - Comparing Automatic vs. Manual Thread Winding Machines

| Feature | Automatic Machines | Manual Machines |

|---|---|---|

| Ease of Use | User-friendly, requires minimal training | Requires skilled operator, more hands-on |

| Production Speed | High speed, suitable for large volumes | Slower, suited for small batches |

| Cost | Higher initial investment | Lower upfront cost |

| Maintenance | Requires regular maintenance, but less frequent | More frequent maintenance needed |

| Flexibility | Less flexible, specific setups | Highly flexible, easy to change setups |

| Error Rate | Lower error rate due to automation | Higher error rate dependent on operator skill |

Maintenance Tips for Prolonging Your Winding Machine's Lifespan

Proper maintenance of your thread winding machine is crucial for ensuring its longevity and optimal performance. Regular inspections should be a part of your maintenance routine, focusing on key components such as the motor, tension controls, and thread guides. Checking for wear and tear, particularly on parts that experience friction and movement, can prevent unexpected breakdowns. Additionally, keeping the machine clean from dust and debris will improve its efficiency and reduce the chances of mechanical failures.

Lubrication is another essential aspect of maintenance that should not be overlooked. Utilizing the appropriate lubricants for the moving parts helps reduce friction and overheating, extending the machine's operational life. It's advisable to follow the manufacturer's recommendations for lubricant types and intervals between applications. Furthermore, ensure that the winding machine is correctly calibrated for the specific thread types you are using; incorrect settings can lead to unnecessary strain on the machine and decrease its lifespan. By adhering to these maintenance tips, you can significantly enhance the durability and reliability of your winding machine.

Thread Winding Machine Efficiency Comparison

This bar chart compares the maximum output of different thread winding machines. The data shows significant differences in performance, which can help manufacturers choose the right machine based on their production needs.

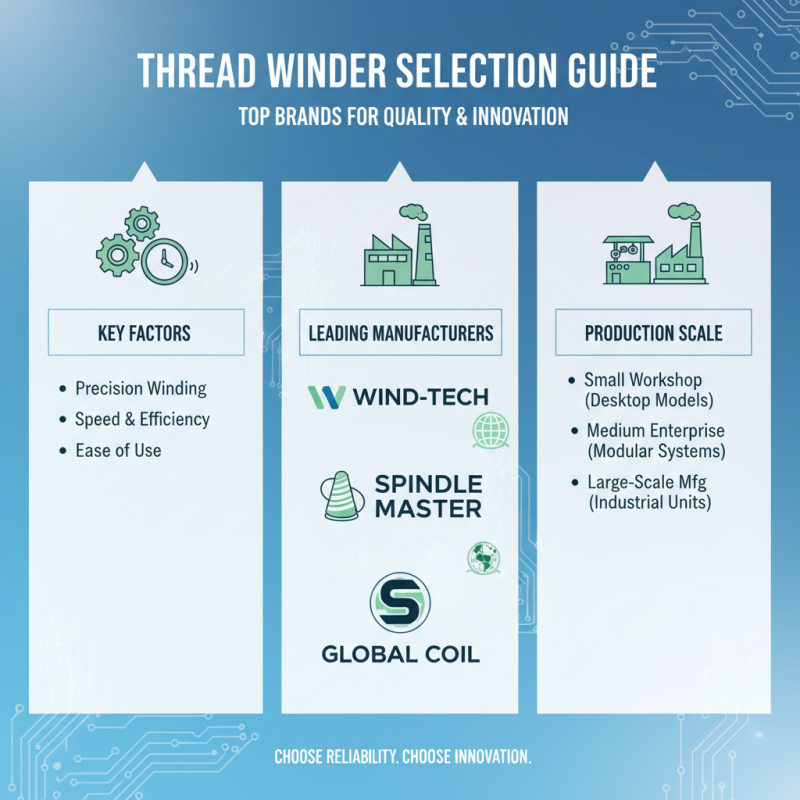

Top Manufacturers and Brands of Thread Winding Machines to Explore

When selecting a thread winding machine, exploring the top manufacturers and brands is crucial to ensuring you choose a quality product that meets your specific needs. Leading manufacturers in the field are known for their innovation, reliability, and cutting-edge technology. They offer a wide range of machines designed to accommodate various production scales, from small workshops to large-scale manufacturing facilities. By focusing on their product features, such as precision winding abilities, speed, and ease of use, you can identify the right machine tailored to your operational requirements.

Additionally, many reputable brands provide exceptional customer service and support, which is vital when investing in machinery. This includes comprehensive manuals, video tutorials, and responsive technical assistance, facilitating a smoother integration into your production line. By researching and reviewing feedback from users of these thread winding machines, you gain valuable insights into their performance, durability, and overall satisfaction. Engaging with user communities or forums can further illuminate the strengths and weaknesses of different machines, assisting you in making an informed decision.

Related Posts

-

How to Choose the Best Yarn Bobbin Winder for Your Knitting Projects

-

Top Benefits of Rapier Looms for Modern Textile Manufacturing

-

Top Benefits of Using a Cone Winding Machine for Efficient Yarn Production

-

Unlocking Efficiency and Precision with the Advanced Bobbin Winder Sewing Machine for Seamless Projects

-

Top 10 Tips for Choosing the Right Twisting Machine for Your Needs

-

Top 10 Best Wool Looms for Crafting Stunning Projects at Home