How to Choose the Best Weaving Machine for Your Textile Business in 2025

As the textile industry continues to evolve, the choice of the right weaving machine becomes crucial for businesses looking to thrive in 2025. According to Dr. Emily Stewart, a renowned expert in textile machinery, "Selecting the appropriate weaving machine is not just about efficiency, but also about embracing future trends to meet consumer demands." Her insights underscore the importance of aligning technology with market needs, making the selection process a strategic endeavor.

In an era marked by rapid technological advancements, understanding the various features and functionalities of weaving machines is essential for maximizing productivity and minimizing costs. Businesses must consider factors such as automation, versatility, and sustainability when making their choice. The challenge lies in distinguishing between machines that merely meet current requirements and those that will adapt to the changing landscape of the textile industry.

Thus, this guide aims to equip textile business owners and managers with the knowledge necessary to navigate the complexities of choosing the best weaving machine. By harnessing expert recommendations and industry trends, stakeholders can ensure their operations are not only efficient but also future-ready—paving the way for success in the coming years.

Understanding Different Types of Weaving Machines Available in 2025

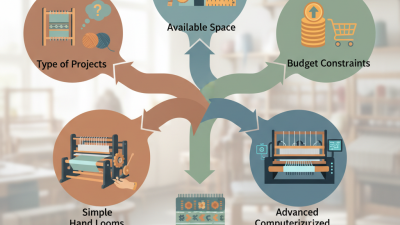

When selecting the best weaving machine for your textile business in 2025, it’s crucial to understand the various types available on the market. Primarily, weaving machines can be categorized into shuttle looms, rapier looms, and air-jet looms. According to a report by Textile Machinery Market Insights, the air-jet loom sector is projected to grow by 5.2% annually due to its efficiency and high-speed production capabilities, which make it ideal for larger operations.

Shuttle looms, although being one of the oldest weaving technologies, are still relevant for producing high-quality fabrics at a lower cost. However, as highlighted in the latest analysis by Global Textiles Research, the demand for shuttle looms is declining as manufacturers increasingly favor the higher flexibility offered by rapier looms. This type of loom provides excellent versatility, enabling businesses to weave varied fabric types without needing extensive setup changes.

Tips: When choosing a weaving machine, consider the volume of production your business requires and the types of fabrics you intend to produce. Conduct thorough research on machine maintenance and support services, as these can significantly impact your overall operational efficiency. It’s advisable to stay updated on technological advancements, as the industry is evolving rapidly, making automation and smart technology more prominent in weaving machines.

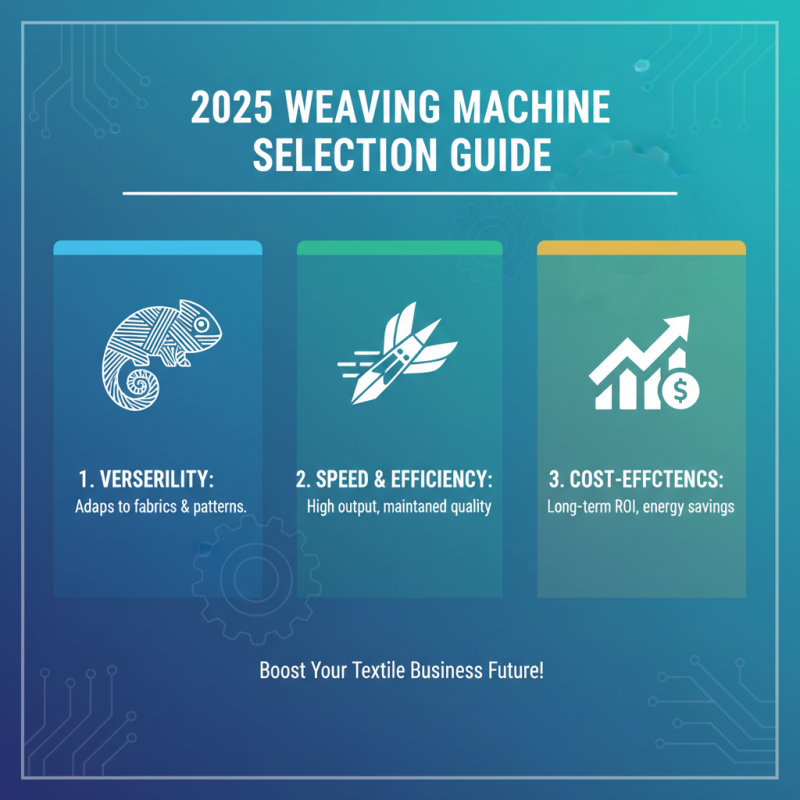

Key Features to Consider When Selecting a Weaving Machine

When selecting a weaving machine for your textile business in 2025, it is crucial to consider several key features that will enhance productivity and efficiency. First and foremost, assess the machine's versatility. A versatile weaving machine can handle various fabric types and patterns, allowing for a broader range of products and adaptability to market demands. Additionally, consider the loom's speed and efficiency; a faster machine may increase output, but it should also maintain quality to avoid fabric defects.

Another important feature to examine is the machine's automation capabilities. Advanced automation not only streamlines the weaving process but also reduces labor costs and minimizes human error. Look for machines equipped with digital controls that allow for precise adjustments and programming of weaving patterns. Furthermore, energy efficiency should not be overlooked, as machines that consume less power are both cost-effective and environmentally friendly, aligning with the growing emphasis on sustainability in the textile industry.

Assessing the Production Capacity and Efficiency of Weaving Machines

When selecting a weaving machine for your textile business in 2025, one of the most critical aspects to consider is its production capacity and efficiency. According to the Textile Machinery Association, advancements in technology have led to significant improvements in weaving machine efficiency, with modern machines achieving production speeds of up to 1,200 meters per minute. This increase in speed not only enhances output but also allows businesses to meet the growing demands of the textile market, which is projected to expand by 5.4% annually over the next five years.

In addition to speed, the production capacity of weaving machines should also be assessed in terms of their adaptability to various fabrics and patterns. Industry reports indicate that machines with versatile capacity can reduce downtime between jobs by as much as 30%, enabling manufacturers to switch between different textiles without extensive reconfiguration. By investing in machines that offer high flexibility and efficiency, businesses can not only optimize their production schedules but also respond swiftly to market trends, thus ensuring a competitive edge in the dynamic textile industry.

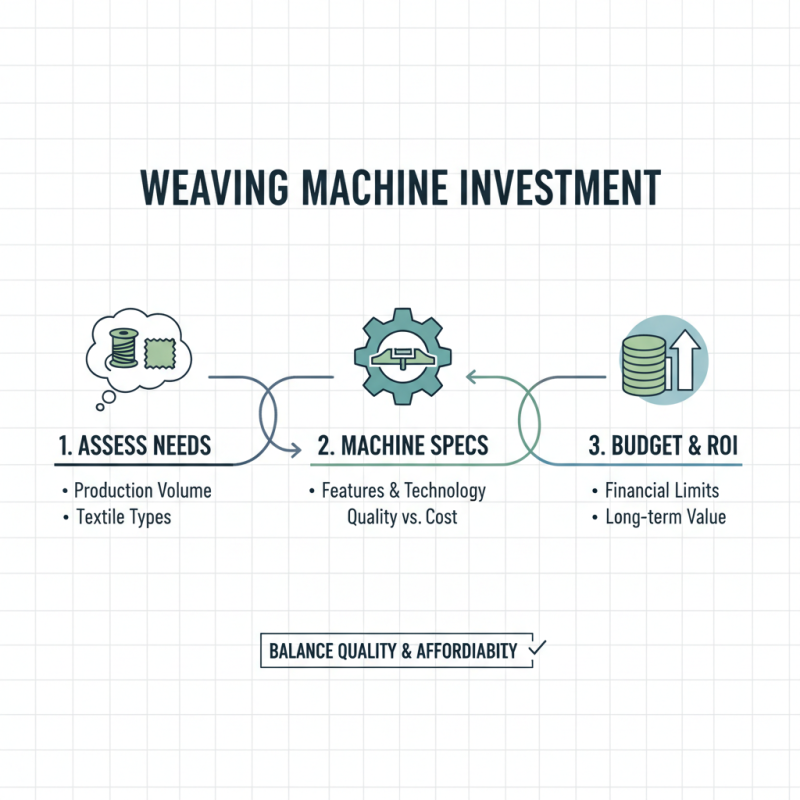

Evaluating Cost and Budget for Weaving Machine Investment

When investing in a weaving machine for your textile business, evaluating cost and budget is crucial. Begin by determining your production needs and the types of textiles you intend to produce. This analysis will help you gauge the specifications and features required in a machine, which can significantly impact its pricing. It's important to strike a balance between quality and affordability, ensuring that your investment aligns with both your operational goals and financial constraints.

**Tips:** Consider creating a detailed budget that includes not only the initial purchase price of the machine but also installation, maintenance, and operational costs over time. This holistic view can prevent unexpected expenses in the future.

Don't forget to research financing options if upfront costs are a concern. Equipment leasing or financing might allow you to spread payments over time, preserving cash flow. Also, evaluating the resale value of the machinery can be vital, as it can affect your overall investment return if you decide to upgrade in the future.

Future Trends in Weaving Technology and Their Implications for Businesses

The ever-evolving landscape of weaving technology is poised to transform the textile industry significantly by 2025. One of the most notable trends is the integration of automation and artificial intelligence in weaving machines. These advancements not only enhance productivity but also allow for the customization required to meet the diverse needs of consumers. Automated assessment systems can reduce human error and optimize the weaving process by adjusting settings in real time to maintain quality and efficiency.

Another crucial trend is the increased focus on sustainability in textile production. Weaving machines of the future are expected to utilize eco-friendly materials and processes, minimizing waste while maximizing energy efficiency. Innovations such as waterless dyeing processes and the use of recyclable fibers will play an essential role in reducing the environmental impact of weaving. As businesses adopt these technologies, they might gain not only a competitive edge but also respond effectively to consumer demand for sustainable practices, thereby aligning business operations with ethical responsibilities.

How to Choose the Best Weaving Machine for Your Textile Business in 2025 - Future Trends in Weaving Technology and Their Implications for Businesses

| Feature | Description | Future Trend | Implications for Business |

|---|---|---|---|

| Automation | Integration of robotic systems to enhance productivity. | Increased reliance on automated processes. | Reduction in labor costs and increased production efficiency. |

| Sustainability | Use of eco-friendly materials and waste-reducing production techniques. | Growing demand for sustainable products. | Attraction of environmentally conscious consumers. |

| Digitalization | Implementation of IoT devices for real-time monitoring. | Shift towards smart factories. | Improved data analysis leading to better decision-making. |

| Customization | Machines allowing for quick changeover and personalized designs. | Increased focus on mass customization. | Ability to meet diverse customer needs effectively. |

| Advanced Software | Utilization of AI and advanced CAD systems for design and production. | Emergence of AI-driven design tools. | Enhanced design innovation and faster time-to-market. |

Related Posts

-

2025 How to Choose the Best Weaving Loom Machine for Your Needs

-

Top 10 Tips for Choosing the Right Textile Machine for Your Business

-

What is Hand Loom Weaving and How Does It Work in Modern Craftsmanship

-

Top 10 Best Wool Looms for Crafting Stunning Projects at Home

-

How to Choose the Best Bobbin Winder Machine for Your Sewing Needs

-

Unlocking Efficiency and Precision with the Advanced Bobbin Winder Sewing Machine for Seamless Projects