Top Benefits of Using a Cone Winding Machine for Efficient Yarn Production

In the dynamic world of textile manufacturing, efficiency and precision play crucial roles in yarn production. Among the various technologies reshaping this industry, the cone winding machine has emerged as a transformative solution that enhances productivity and quality. According to renowned textile expert Dr. Emily Carter, “The cone winding machine is not just a tool; it is a game changer for yarn manufacturers seeking to optimize their operations and reduce waste.” This innovative machine streamlines the winding process, ensuring a uniform and high-quality end product, which is essential for meeting the exacting demands of today's market.

As manufacturers increasingly strive to balance productivity with sustainability, the cone winding machine stands out for its ability to minimize yarn breakage and maximize yield. Its sophisticated mechanisms enable precise control over the tension and winding process, allowing for a more consistent and reliable output. In a time when efficiency dictates success, investing in this technology not only enhances operational capabilities but also contributes to a more sustainable production cycle, positioning businesses for growth in a competitive landscape.

In summary, the cone winding machine represents a pivotal advancement in yarn production technology. By adopting this innovative equipment, manufacturers can not only increase their efficiency but also ensure superior quality in their products, ultimately leading to higher customer satisfaction and retention. Embracing such advancements is essential for those looking to thrive in the evolving textile industry.

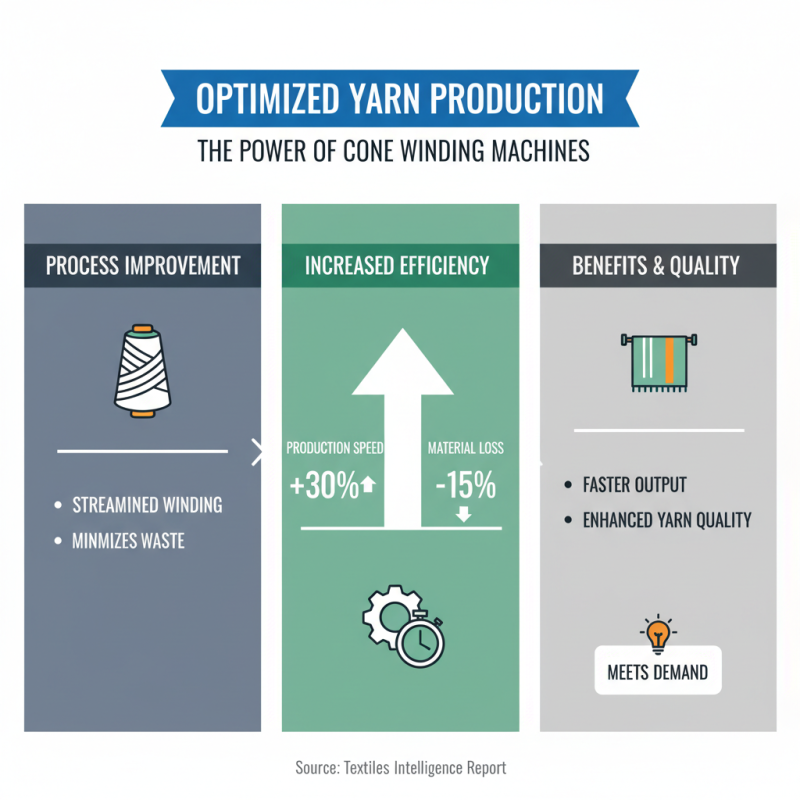

Benefits of Optimized Yarn Production with Cone Winding Machines

Optimized yarn production is crucial for the textile industry, and one effective way to achieve higher efficiency is through the use of cone winding machines. These machines streamline the winding process, minimizing waste and maximizing productivity. According to a report by Textiles Intelligence, companies that implement advanced winding techniques can increase their production speeds by up to 30% while reducing material loss by approximately 15%. This improvement not only accelerates output but also enhances the quality of the final yarn products, meeting the growing demands of manufacturers and consumers alike.

Additionally, cone winding machines contribute significantly to maintaining consistent tension and uniformity in yarn dimensions. The precision offered by these machines helps in creating high-quality yarns that are essential for various applications, from fashion to industrial textiles. Industry experts suggest that with optimized processes, businesses can experience a reduction in downtime as well; some estimates indicate that efficient winding operations can lead to a 20% decrease in machine maintenance needs. This aspect highlights the role of cone winding machines in not just meeting production goals but also ensuring operational sustainability in the yarn production sector.

Improved Yarn Quality Through Precision Winding Techniques

The improved quality of yarn produced through precision winding techniques is a game changer in the textile industry. By utilizing a cone winding machine, manufacturers can achieve consistent tension and uniform diameter in yarn production. This level of precision is essential for creating high-quality yarns that meet the demanding standards of modern textile applications. Each wound cone ensures that the yarn maintains its integrity, reducing the occurrence of defects and enhancing overall performance in subsequent fabric processing.

Tips for maximizing yarn quality include regularly maintaining the winding machine to ensure smooth operation and optimal tension consistency. Additionally, selecting the appropriate winding speed based on the type of yarn can further enhance quality, as faster speeds may introduce unnecessary stress that could compromise the yarn's strength. Monitoring environmental conditions, such as humidity and temperature, is also crucial, as these factors can impact the winding process and the finished product.

When using a cone winding machine, it is vital to pay close attention to the yarn feed and take-up systems. Correctly aligning these elements can significantly reduce slippage and improve the quality of the final product. Employing skilled operators who understand the intricacies of the winding process can further lead to better quality yarn, resulting in fewer reworks and higher customer satisfaction.

Increased Production Efficiency with Automated Winding Processes

The use of a cone winding machine significantly enhances production efficiency in yarn manufacturing. Automated winding processes streamline the entire operation, allowing for faster completion of tasks that would typically require considerable manual labor. By integrating advanced technology, these machines minimize the risk of human error, ensuring consistent quality and precision in yarn production. With the ability to process vast amounts of yarn continuously, manufacturers can meet increasing demands without compromising on standards.

Moreover, the automation provided by cone winding machines reduces downtime in production cycles. With features like automated thread break detection and self-correction, these machines promptly address issues that might interrupt the winding process. As a result, they facilitate uninterrupted workflow, which ultimately leads to higher output rates. Enhanced control over tension and winding tension adjustments further contributes to producing high-quality yarn, which is essential for various textile applications.

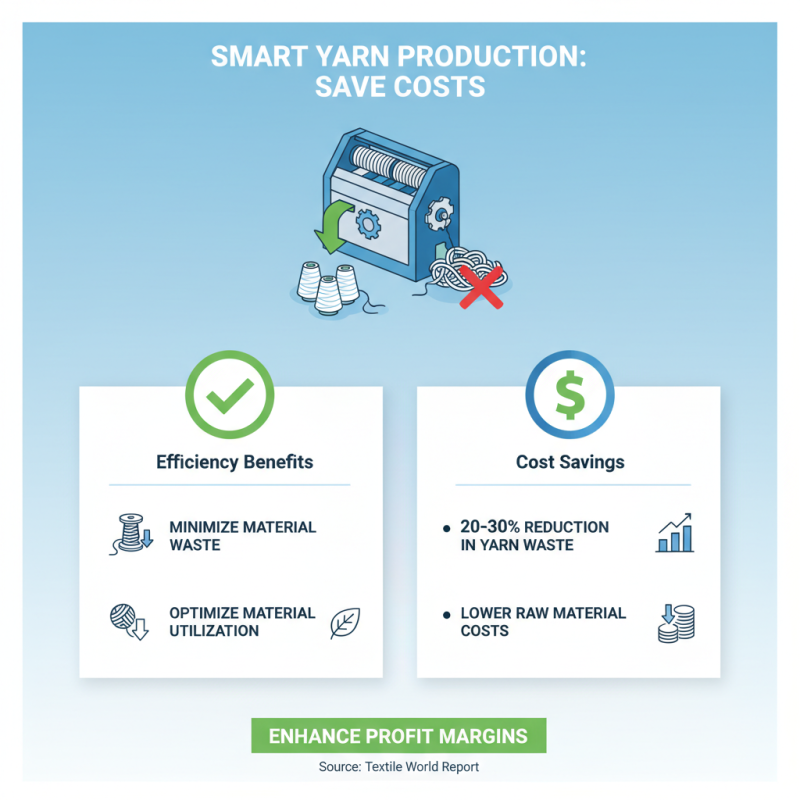

Cost Savings Achieved by Reducing Material Waste During Production

The efficient use of a cone winding machine can lead to significant cost savings in yarn production, primarily by minimizing material waste. According to a report by the Textile World, companies using advanced winding technology have observed a 20-30% reduction in yarn waste during production. This decrease not only optimizes material utilization but also translates to lower raw material costs, allowing manufacturers to enhance their profit margins while maintaining competitive pricing.

Furthermore, a study by the International Textile Manufacturers Federation indicates that effective yarn winding processes can improve overall production efficiency by up to 15%. By automating the winding process and ensuring precise tension control, these machines reduce errors and inconsistencies that often lead to material loss. As a result, production lines can run more smoothly, with fewer interruptions due to quality control issues. This streamlined approach not only safeguards profits but also promotes sustainability in the industry, as less waste contributes to a lower environmental footprint.

Enhanced Flexibility for Diverse Yarn Types and Customization Needs

The enhanced flexibility of a cone winding machine significantly benefits manufacturers dealing with diverse yarn types and customization needs. These machines are designed to accommodate various yarn materials, from natural fibers like cotton and wool to synthetic options such as polyester and nylon. This adaptability allows producers to switch between different yarn types seamlessly, facilitating quick responses to changing market demands. As a result, manufacturers can experiment with unique blends and textures without committing to costly retooling processes, ensuring a smooth production flow.

Moreover, cone winding machines offer advanced features that support intricate customization requirements. With precision control over winding tension and speed, users can tailor the winding process to achieve specific qualities, such as improved yarn strength or enhanced appearance. This level of customization opens new avenues for creative design, enabling manufacturers to develop specialized products that cater to niche markets. Consequently, businesses can meet the specific needs of their clients while maintaining high standards of quality in their yarn production. The incorporation of these machines ultimately fosters innovation and versatility, vital for staying competitive in the textile industry.

Top Benefits of Using a Cone Winding Machine for Efficient Yarn Production

Related Posts

-

2025 Top 5 Loom Fabric Trends: Innovative Designs and Sustainable Choices

-

Top 10 Tips for Choosing the Right Textile Machine for Your Business

-

Top 10 Tips for Choosing the Right Twisting Machine for Your Needs

-

What is a Bobbin Winder Machine and How Does It Work Explained

-

Top 7 Weave Fabric Types You Need to Know for Your Next Project

-

10 Best Yarn Winding Machines for Effortless Crafting and Production