2026 Top Loom Machine Trends You Need to Know About

As we look ahead to 2026, the loom machine industry is undergoing significant transformations. Innovations are shaping how fabrics are produced and enhancing efficiency. This year marks a turning point. Many companies are investing in advanced technology to meet rising demands.

The latest loom machines feature smart technologies. These machines are not just faster; they are also more precise. They allow for intricate designs that were previously challenging. Sustainability is also a key focus. More manufacturers are opting for eco-friendly materials and processes. It’s crucial to reflect on these changes.

However, challenges remain. Not all businesses can afford to upgrade their equipment. Some may struggle to keep up with trends. This shift demands a reevaluation of current practices. Staying informed about loom machine advancements is essential for success. Embracing change can lead to opportunities in this evolving landscape.

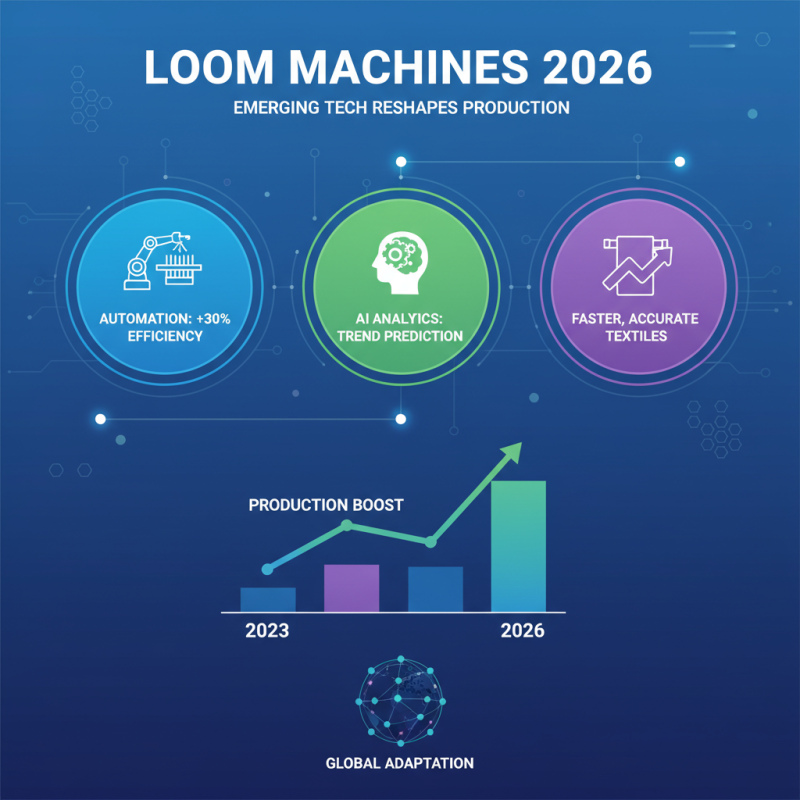

Emerging Technologies Influencing Loom Machine Development in 2026

Emerging technologies are reshaping the loom machine landscape in 2026. Automation and artificial intelligence play pivotal roles. A recent report indicates that automation can enhance production efficiency by 30%. This leap ensures textiles are produced faster and more accurately. Additionally, AI-driven analytics help manufacturers predict trends and adapt quickly.

The integration of IoT (Internet of Things) technology is another significant trend. Loom machines are becoming smarter, connected devices. They can monitor performance in real-time. This connectivity improves maintenance schedules and reduces downtime. Manufacturers report that IoT can lower maintenance costs by 25%.

**Tips:** Always keep your equipment updated. Outdated machines can hinder your productivity. Embrace training programs for staff. Skilled operators maximize new technologies effectively. Invest in data analysis tools. They provide insights translating to better operational decisions.

Sustainable Practices in Loom Machine Manufacturing for Environmental Impact

The textile industry is undergoing a significant transformation, particularly in loom machine manufacturing. Sustainable practices are at the forefront, addressing environmental concerns. Reports indicate that textile waste contributes to about 10% of global carbon emissions, underscoring the urgency for change.

Loom machine manufacturers are adopting eco-friendly materials. Using recycled components can dramatically reduce waste. Some studies show that up to 50% of industry waste can be minimized through better material sourcing. Innovative technologies are emerging to enhance efficiency. These machines now consume less energy while maintaining output.

**Tip:** Consider integrating energy-efficient technologies in your manufacturing process. Even small improvements can make a difference.

Additionally, regular maintenance helps optimize machine performance. It’s essential to monitor and reduce emissions during production. A recent analysis highlighted that overlooked machinery can increase carbon footprints by significant margins. The industry is slowly realizing that sustainability isn’t just an option; it’s a requirement for survival.

**Tip:** Regular audits can identify areas for improvement in sustainability practices. Assess your current methods to align with best practices.

Automation and IoT Integration in Modern Loom Equipment

The integration of automation in modern loom equipment is revolutionizing the textile industry. Many manufacturers are adopting smart technologies to enhance efficiency. IoT integration allows machines to communicate and share data, leading to improved production workflows. This connectivity enables real-time monitoring of performance and condition.

However, this shift brings challenges. Training workers to adapt to new technologies is essential. Many may feel overwhelmed by the rapid pace of change. Additionally, maintenance needs can increase with more complex equipment. Environmental concerns are also rising, as energy consumption may spike with extensive automation. Striking a balance between innovation and sustainability is crucial for long-term success.

Adopting automation and IoT is not just about cutting costs. It involves a rethink of how production processes are designed. The industry must reflect on how these technologies impact craftsmanship and worker roles. Integrating new systems while respecting traditional methods is a delicate balance to strike. The journey toward modernization is fraught with obstacles, but the potential for positive change is immense.

Innovative Fabrics and Their Influence on Loom Designs and Functionality

The evolution of loom machines is significantly driven by innovative fabrics. Designers now experiment with diverse materials such as biodegradable fibers and smart textiles. These new fabrics influence loom designs, making them more versatile. For instance, the demand for sustainable textiles rose by over 30% in the last three years. This shift impacts how looms are built and what features are prioritized.

Improvements in technology also shape modern looms. Automation allows for greater precision and efficiency. Reports indicate that advanced machinery can increase production speed by up to 50%. However, adapting to these advancements is crucial for manufacturers. Some may struggle with integrating new technology into their existing systems.

Tips: Stay informed about fabric trends. Explore options that align with your production capabilities. Consider investing in training to help your team adapt. Embracing innovation may seem daunting, but it can lead to greater market opportunities. Regular assessment of your current processes can identify areas for improvement, enhancing overall productivity and sustainability.

2026 Top Loom Machine Trends You Need to Know About - Innovative Fabrics and Their Influence on Loom Designs and Functionality

| Trend | Description | Impact on Loom Design | Innovative Fabric Types |

|---|---|---|---|

| Smart Loom Technology | Integration of IoT for real-time monitoring and control. | Enhanced connectivity and programmability in designs. | Smart textiles, wearables. |

| Sustainable Materials | Use of biodegradable and recycled fibers. | Adjustments in machinery to handle varied materials. | Recycled polyester, organic cotton. |

| 3D Weaving Technology | Incorporation of multi-dimensional weaving. | Complex and innovative design capabilities. | Geotextiles, composite materials. |

| High-Speed Weaving | Advancements in speed with precision. | Looms designed for high efficiency. | Performance fabrics, technical textiles. |

| AI-Driven Design | Artificial intelligence for pattern creation and optimization. | Customizable settings based on data analytics. | Fashion fabrics, high-tech apparel. |

Market Demand and Consumer Trends Shaping the Loom Industry in 2026

In 2026, the loom industry will experience significant shifts driven by market demand and evolving consumer preferences. Reports indicate a 15% annual growth in textile production, influenced by the increasing popularity of sustainable materials. Consumers are becoming more aware of eco-friendly options. They prefer looms that use less energy and produce minimal waste. This change is crucial for manufacturers aiming to attract a modern audience.

Amid rising demand, innovation is key. Automated looms are gaining traction, as they enhance efficiency. According to an industry report, smart looms can reduce production time by 30%. However, not all manufacturers can keep pace with this shift. Many still rely on outdated technology. This poses a challenge for companies hoping to compete. They must invest in new systems or risk falling behind.

**Tip:** Consider adopting sustainable practices now. It could save costs and improve your market position.

As consumer values evolve, businesses must adapt. The focus on social responsibility will continue to grow. Manufacturers should align their offerings with these changing expectations. Proactive adaptation to consumer demands is vital for thriving in this competitive market.

**Tip:** Regularly gather feedback from customers. Understanding their needs will help shape your product development.

Related Posts

-

Top 10 Tips for Choosing the Right Textile Machine for Your Business

-

Top Benefits of Rapier Looms for Modern Textile Manufacturing

-

Top 10 Best Wool Looms for Crafting Stunning Projects at Home

-

Top 10 Weaving Bobbin Winders of 2023: Boost Your Efficiency by 30%

-

Ultimate Guide to Choosing the Best Yarn Twister for Your Knitting Projects

-

Top Benefits of Using a Cone Winding Machine for Efficient Yarn Production